When we arrived three years ago as DIY expats, we were blown away by Eindhoven’s technology and the scope and sophistication of its businesses. Saturday’s DTW High Tech Discovery Route organized by Brainport and BOM showed us sides of the city we’d never seen … and that everything here connects back to electronics giant Philips.

This was the second year we were invited to join the tour, part of Dutch Technology Week. Last year’s event was at High Tech Campus, where we work. This year, the tour departed from Strijp-T, adjacent to Strijp-S, which is the center of Eindhoven’s creative class, as well as an ongoing housing, retail and business transformation.

Strijp-T is yet another section of what had been Philips’ city-wide network of factories, warehouses and R&D complexes (entire districts of the city, really) left over from when it was a huge consumer brand making everything from CDs and players to lighting.

Now, Strijp-T’s once-abandoned buildings are home to new creative companies and next-gen manufacturing, none of which we’d seen first-hand till now.

The day began at Innovation Powerhouse on Zwaanstraat, which had housed the coal-fired generators powering Philips’ manufacturing. Now, it’s full of design companies including VanBerlo, one of the most successful design houses in the Netherlands.

The day wrapped four-and-a-half hours later at Philips’ manufacturing facilities in Best, which includes its just-opened Philips Customer Experience Center.

Our takeaway was a better understanding of this tech boomtown … that there’s far more going on here than ASML cornering the photolithography business. While smaller after restructuring and spinoffs, Philips is still a flourishing foundational business for Eindhoven. But there’s also a whole New Wave of business coming online such as Additive Industries, which is in a former Philips Building a two-minute walk from the Innovation Powerhouse.

Here are the highlights of everything we saw.

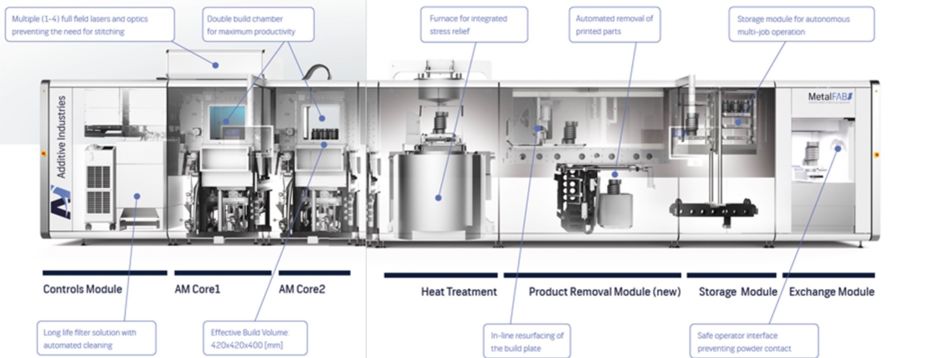

• Dispatches has written a lot about Additive Industries, and we saw their pitch at High Tech Connect last September. But we didn’t get it until we visited their facilities during DTW.

(Editor’s note: Additive Industries didn’t allow photos of their equipment during the visit.)

Additive Industries is a 3D printing company, but on a whole different level of scale and sophistication than what we’re used to. Instead of small devices printing layer upon layer of plastic or whatever material to create a product, Additive Industries builds room-sized industrial printers. Those printers use advanced technology such as lasers to melt, say, titanium power at 2,000 degrees Centigrade.

That liquid metal is printed into whatever sort of flange, coupler or widget according to the customers’ technical specifications.

In this world, clients need more than just one-off items … they need large parts for things like rocket-motor components that aren’t compromised by the casting process. Additive Industries customer segments include aviation, aerospace, auto industry and even Formula 1 teams such as Alfa Romeo, said Bart Horsten, an engineer and manager.

And by the way, Additive Industries builds their giant printers for clients who can download their designs as simply as through a thumb drive. But AI doesn’t do printing.

• In the lobby of the Innovation Powerhouse, we got a demonstration of new personal air mobility from the Talaria team at Technical University of Delft. The team is building an electric helicopter for the Boeing-sponsored GoFly competition in the United States, with a $1.6 million prize to the team that can fly 91 kilos for 30 minutes.

The craft can weigh no more than 220 kilos, including the pilot.

The students did much of the fabrication themselves, including the carbon-fiber composite material of the helicopter blades. This might be a student effort, but Talaria has assembled an impressive 25-member team that includes aeronautical engineering, industrial design and mechanical engineering talent. And one mining engineer, because you never know when you’ll strike gold, right?

• VanBerlo is an industrial and consumer design firm that takes up most of the first floor (second floor, if you’re American) of the Innovation Powerhouse.

VanBerlo is an amazing firm in an amazing space, a huge loft-style workspace. Roelof van Driel, design director, and founder Ad van Berlo showed the tour some of the cooler products they’ve developed, from the dashboards of port tugs to the LifeSaver, an intuitive, app-enhanced CPR device to the evolution of MaxiCosi baby seats from simple safety seats to smart devices that use iPad technology to make certain the seat is installed and positioned properly as children get bigger.

VanBerlo is a global company that uses “mobile Internet teams” to work with a lot of high-profile, consumer-facing brands.

On top of that, VanBerlo is the kind of creative, stimulating corporate culture and workspace (complete with giant trees) that makes you say, “Gee, I wish I worked here.”

• At Philips’ new Customer Experience Center, the first stop was a dazzling piece of consumer technology, a Bluetooth-connected SmartMirror. The SmartMirror, which the company debuted at the Consumer Electronics Show earlier this year in Las Vegas, acts as a hub for smart health and personal care products such as its Sonicare toothbrushes, Philips’ smart shaver, heart and blood pressure monitors, third-party activity trackers and a scale. It can display your health trends and even how efficiently you brush your teeth.

Something everyone needs? Maybe not, but neither is a Ferrari, and they seem pretty popular.

The theme of the visitor center is that Philips – one of the big three health care tech companies along with Siemens and GE – is redefining the healthcare business by listening to providers, patients, parents and ordinary consumers. Major Philips business categories include equipment for smart hospitals including ICUs, diagnostics, neonatal units and aging-care facilities.

Which we kind of knew from last year.

What we’d never seen is where it all comes together … and hundreds of millions of euros worth of the latest equipment all in one place.

John van Soerland, vice president of operations at the facility, hosted the English-speaking group and showed us the factory floors where equipment such as the latest CT scanners and hybrid surgical systems are assembled. This is not a one-size-fits-all business. The most advanced equipment is tailor-made and installed by Eindhoven-based crews according to the projected clinical needs and business projections (and budgets) of the client hospitals, van Soerland said.

In the past few years, Philips doubled-down on healthcare and it’s paid off. Philips now has a 50-share of image-guided therapy market, he said.

Interestingly, though Philips left Eindhoven 35 years ago for a new headquarters in Amsterdam, only about 1,000 employees work there as the company’s total workforce has fallen to about 78,000 in 2018 from as many as 125,000 in the late 2000s. (Most of the attrition is due to Philips spinning out huge companies including NXP and Philips Lighting, now Signify.) The Eindhoven workforce, which includes manufacturing and research, is about 8,500 people, according to Philips own figures.

Though the tour came at the end of a long week that included Female Tech Heroes and other Dutch Technology Week events, we wouldn’t have missed this for the world. And it was that rare event that turned out to be better than anticipated.

Program

10:30: Reception at Strijp-T with some coffee and tea at EAST. Zwaanstraat 31F, 5651 CA Eindhoven.

11.00: Guided tour at Strijp-T, where we will visit several locations/companies, including Additive Industries.

12.00: Lunch at restaurant EAST at Strijp-T.

13.00: Towards Philips Health with the touring car

13.20: Guided tour at Phillips Health in Best

14.30: Return to Strijp-T with the touringccar

15.00: Arrival at Strijp-T, Zwaanstraat 31 A-J.

Co-CEO of Dispatches Europe. A former military reporter, I'm a serial expat who has lived in France, Turkey, Germany and the Netherlands.